How to select load cells

Selecting the right equipment for your needs. Depending on the application there are many suitable types of load cell available. Each model has its uses and the right choice will depend on your needs. Here’s our guide to the different options available. It outlines the specifications and technical details to consider in each option.

Loading Conditions

- Maximum operating load: This is the maximum operating load, weight or force the unit is capable of withstanding. Weights or forces above this level are likely to overload or damage the unit and determine the rated load of the cell.

- Maximum measurable load. This is the maximum force or weight that the clue is able to measure accurately during normal use. Loads over this weight or force can cause damage to the unit or result in inaccurate results even if under the maximum operating load.

- Loading method: This provides basic information on how the load can be applied to the unit (tension, compression or both). When choosing a load cell this is an important point to bear in mind as it affects how you load the unit.

- Units measured: Depending on your required application this is important to bear in mind. Common units measured include: Tonnes, newtons and kilonewtons, grams and kilograms and pounds.

- Accuracy: Ensuring the unit you select is able to withstand the load you need to measure and produce accurate results in a relevant unit is vital. This is expressed commonly as +% of full output (FSO) for the rated load for the cell.

- Signal Output: Most load cells gave a range of options available. Some are fitted with signal amplification and display built in, while others allow for external instrumentation to be connected by wire or wirelessly. These may be analog or digital depending on the model.

Depending on the application you may need to consider the ability of the unit to withstand adverse conditions. These include overloading, extreme temperature thresholds and resistance to fatigue.

- Thermal errors: In some instances (catering, manufacturing, etc) it may be important to have a unit capable of accurate results in a variety of temperature ranges. This is listed as +%FSO at X degrees C or F.

- Overload range: If you need to measure a wide range of weights and forces you will need a load cell capable of measuring a wide range of loads accurately and safely. Some units have great accuracy at low weights, some at high, and some allow for good results across a broad weight range.

- Dynamic range: Some units also have a dynamic load threshold which allows you to judge the ability of the unit to resist sudden high loads.

- Fatigue Load: Some units are designed to resist regular high-volume usage and are suitable for industrial use, other units are less able to resist the fatigue that comes with high-use cycles. Selecting a unit that is able to withstand your maximum usage requirements is important and will help you avoid having to keep replacing units.

- Environmental concerns: Units that are capable of functioning indoors within a set range of temperatures may not be right for every application. Some units are designed for use indoors and outdoors at extreme temperatures. It’s also important to consider whether the unit is capable of resisting these temperatures while in storage.

Physical parameters

Depending on your needs it may be essential to focus on the physical size, shape, and features of each cell. Picking one that isn’t an appropriate size could result in the unit not functioning properly or being unusable within the required space.

- Size specifications: Another key element in choosing a load cell is selecting one that fits your space. If you are attaching the load cell to an existing rig it may be necessary to acquire exact measurements of each unit before making our selection. If you have space available it’s often possible to be less particular about size and focus on other features you require. If you intend to measure a range of loads you may need a load cell with specific access options. It may be more practical to select certain cells above others. We can advise on this based on your needs

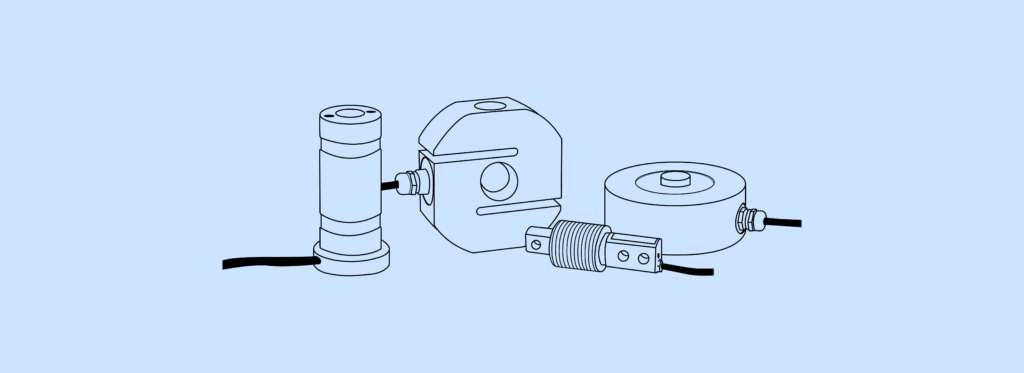

- Mount style / Attachment: Options include Column, low profile, miniatures, and threaded tension compression load cells. St type, load shackles, and beam load cells. More information is provided on the individual listing page for each type of cell. Each model has a different set of attachment options. These vary from model to model and include: Threaded joints, Clevis pins, pulley bearings, flange mounts etc. Your needs will depend on what the unit will attach to and should be chosen to fit existing fittings where possible.

Other requirements

Each business is unique and your needs are likely to be just as individual. Some units have specific features (method of testing, certification, minimum quality thresholds etc). For example some customers require a specific number of units that will work together, are tested to a certain threshold and we’re all built to exacting specifications by the same manufacturer. We can assist with a range of needs and can advise you on choosing the model that is right for you. If you require larger quantities of cells or have specific delivery requirements we can assist with this too.