Running line tensionmeters - Research vessel Dana

The ultimate test

Overloading equipment and experiencing malfunctions hundreds of miles from shore is both costly and time-consuming. When working in uncontrolled environments, like the North Sea, hazardous situations may occur when you least expect it – especially if you can’t measure the forces in play.

In order to get a reliable load indication when trawling, ship inspector Jens Krogh contacted Vetec and asked if our Running Line Tensionmeters could provide the certainty needed. Three tensionmeters were installed and they have each served two years as overload monitoring systems. Since then, there has been no incidents and therefore no interference with Dana’s important work.

Research vessel Dana

Dana is the largest research vessel in Denmark creating the empirical foundation for scientific research and recommendations at DTU Aqua.

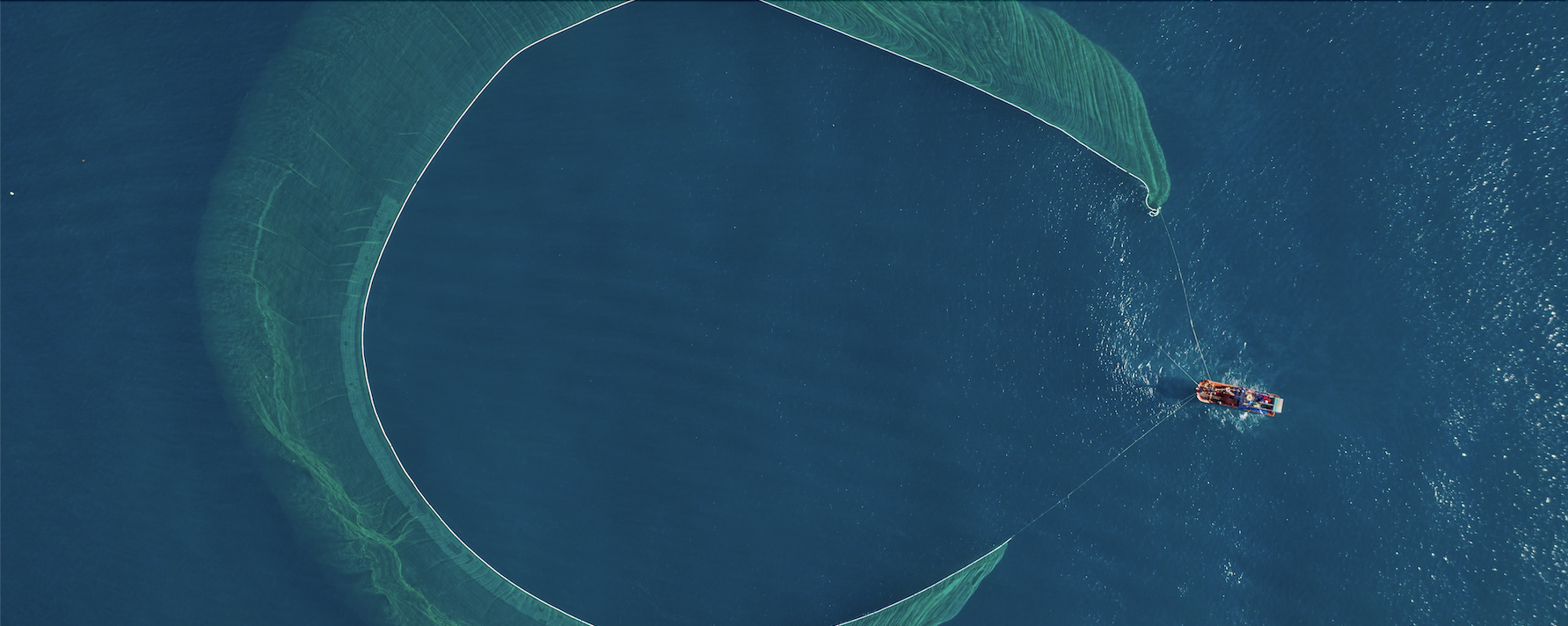

One of the major tasks for Dana is the collection of data in order to monitor the state of Danish and European seas. Most samples are collected via a 2,5 kilometer trawl and the samples are processed right away in the onboard labs.

Dana is an interesting case since maritime conditions are the ultimative test of electronic equipment. Vetec’s Running Line Tensionmeters were mounted on the existing trawling wires on deck, meaning extreme temperatures, seawater contact and constant beatings – without breaking down. A Running Line Tensionmeter lowers the risk of unwanted incidents and equipment malfunctions – and in this case we count two years without downtime.

Now we know if we're overloading the wires. This means fewer repairs and less downtime"

Jens Krogh Nielsen

Ship Inspector at DTU Aqua

Reliable engineering

A Running Line Tensionmeter is a construction of three load pins, giving three separate load indications. The three data-streams are calculated into one single indication, providing a continuous data-stream for easy load monitoring. The design allows the wires to move freely through the tensionmeter, and it is therefore very easy to add to existing setups.

The proven design is all about functionality and therefore superfluous elements has been left out. The Running Line Tensionmeters from Dana has been in service for two years, in extremely demanding conditions. The maintenance of Dana’s Running Line Tensionmeters shows no technical issues after two years of operation and has only required a substitution of wear parts and a standard calibration of the load cells.

If you have further interest in the research vessel Dana, please visit Dana’s official website.