Load Cells

All load cells from Vetec are designed for precision, ease of use and high durability. Our range covers all types of products for load monitoring and weighing solutions, giving value through innovative thinking. Our products usually help customers improve cost-effectiveness, safety and various work processes.

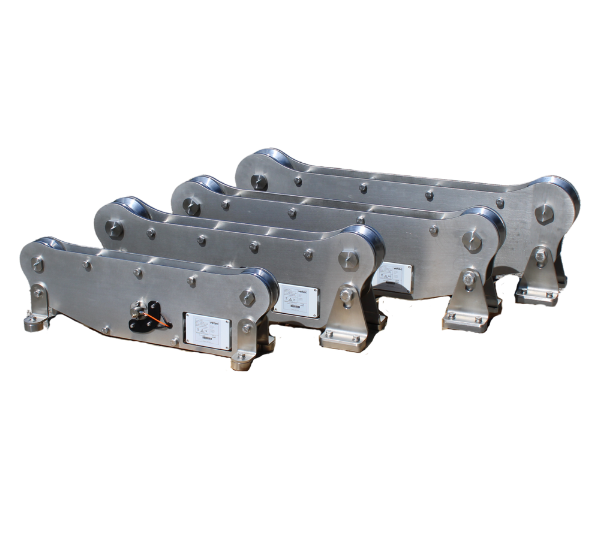

Bolt-on strain gauge sensors

Other load cells

Tension or compression?

If you don't know what you need you might learn something here - or else do not hesitate contacting us.

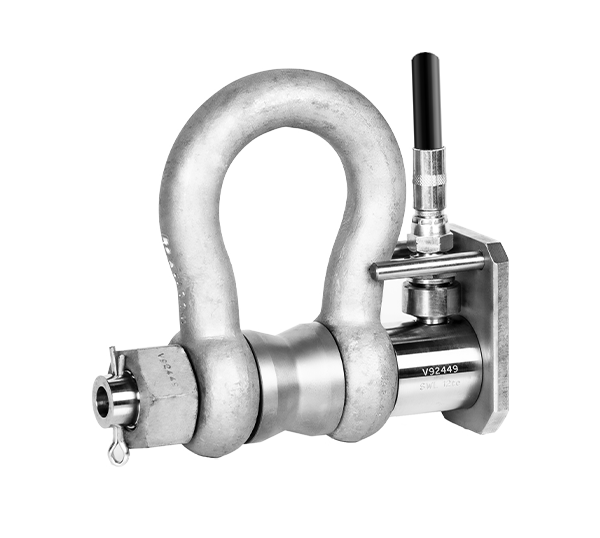

What is a tension load cell?

A tension load cell is a type of load cell that is used to measure tension or pulling force. It works by converting a tension force into an electrical signal that can be read and processed by electronic equipment. Tension load cells are typically cylindrical in shape, with a central hole through which a load-bearing cable or rod can be threaded. The load cell consists of a strain gauge, which is a small device that changes resistance when it is subjected to a mechanical force. The strain gauge is attached to the load cell body, and as the cable or rod is tensioned, the strain gauge detects the amount of strain and sends an electrical signal to a measurement instrument, such as a digital indicator or data logger, which can be used to calculate the tension in the cable or rod.

Tension load cells are widely used in many industries and applications, such as testing equipment, material handling, and manufacturing processes. They are also commonly used in hoisting and lifting operations, where it is critical to accurately measure the weight of an object, and to ensure that equipment is not overloaded.

Tension load cells are usually made from rugged materials such as alloy steel, and are designed to be highly accurate and withstand a wide range of environmental conditions. However, due to the nature of its use, it is also designed to be highly durable, and capable of resisting damage from impact, vibration, and other types of mechanical stress.

To sum it up, a tension load cell is a device that can be used to measure tension or pulling force by converting it into an electrical signal and outputting it to be measured by electronic equipment. It is widely used in a variety of industries and is critical in many applications like material handling and lifting operation.

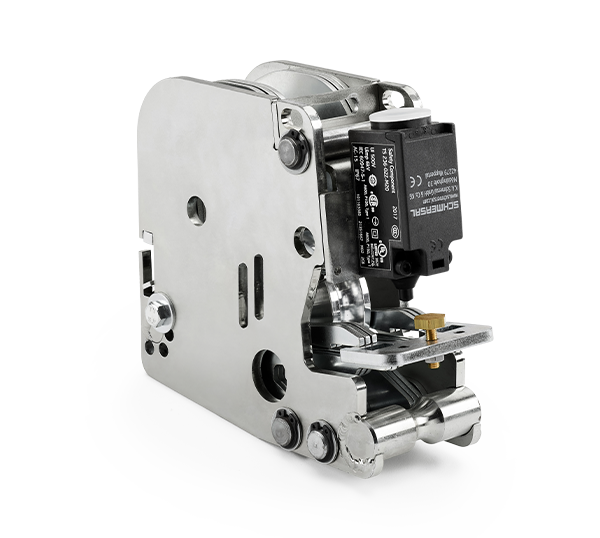

What is a compression load cell?

A compression load cell is a type of load cell that is used to measure compressive force, or the force exerted on an object when it is squeezed or compressed. Like tension load cells, compression load cells convert a mechanical force into an electrical signal that can be read and processed by electronic equipment.

Compression load cells typically have a cylindrical or rectangular shape and have a hole at the top where a load can be applied. The load cell is typically made from a material such as alloy steel and contains a strain gauge, which changes its electrical resistance in response to a compressive force. As the load is applied, the strain gauge generates an electrical signal that is sent to a measurement instrument, such as a digital indicator or data logger, which can be used to calculate the compressive force on the load cell.

Compression load cells are commonly used in applications that require accurate weight measurement such as weighbridges, testing equipment, and manufacturing processes where it is critical to check the compressive strength of material. They are also used to measure force exerted in industrial and commercial applications such as force required to press and form materials.

Similar to tension load cells, compression load cells are designed to be highly durable and capable of resisting damage from impact, vibration, and other types of mechanical stress. The materials and design are usually robust and able to withstand a wide range of environmental conditions.

To sum it up, a compression load cell is a device that measures compressive force and converts it into an electrical signal output to be read by electronic equipment. It is typically cylindrical or rectangular in shape and has a hole at the top for applying a load. It is widely used in various applications such as weighbridges, force measurements and testing equipment, manufacturing processes and many other industrial and commercial applications.

What is a bolt-on load cell?

A bolt-on load cell is a type of force sensor that is designed to be mounted between two structural elements to measure the force being applied between them. It typically consists of a metal block with a threaded hole in the center that allows it to be bolted to one of the structural elements, and a threaded stud protruding from the opposite side that attaches to the other structural element.

When a force is applied to the two structural elements, it causes the bolt-on load cell to deform slightly. This deformation changes the electrical resistance of a strain gauge attached to the load cell, which can be measured and used to calculate the force being applied.

Bolt-on load cells are commonly used in industrial applications where it is necessary to monitor forces in machinery, equipment, and structures. They are often preferred over other types of load cells because they are easy to install, can be easily replaced, and do not require any modifications to the existing structure.

IP class

High IP classifications. Ideal for wet, humid and dusty environments.

Material

High quality stainless steel. Certified Toolox 33 or Impax Supreme steel.

Precision

All load cells are top performers with acknowledged weighing accuracy.

Service centre

In-house service centre with instant support, repairs and service.

How do you select a load cell?

There are several factors to consider when selecting a load cell.

Capacity

The load cell must be able to handle the maximum load that will be applied to it. It is important to select a load cell with a capacity that exceeds the maximum load by a factor of at least 2-3 times.

Accuracy

The accuracy of the load cell will affect the precision of the measurements. Choose a load cell with the highest accuracy that is within your budget.

Output signal

The output signal of the load cell will depend on the type of measurement system you are using. Make sure the load cell’s output signal is compatible with your measurement system.

Temperature sensitivity

Some load cells are sensitive to temperature changes, which can affect their accuracy. If the load cell will be used in a location with significant temperature fluctuations, consider selecting a load cell with low temperature sensitivity.

Environmental conditions

The load cell must be able to withstand the environmental conditions in which it will be used. For example, if it will be used outdoors, it must be able to withstand extreme temperatures, humidity, and other weather conditions.

Size and shape

The size and shape of the load cell should be appropriate for the application. Consider the space constraints and the shape of the object being measured.

Price

The cost of the load cell should be considered, but it should not be the only factor. A higher-quality load cell may cost more, but it may also provide more accurate and reliable measurements.

By considering these factors, you can select a load cell that is well-suited for your application and budget.